News detail

The centralized injection molding feeding system is a highly automatic material supply and distribution system

2023-04-18

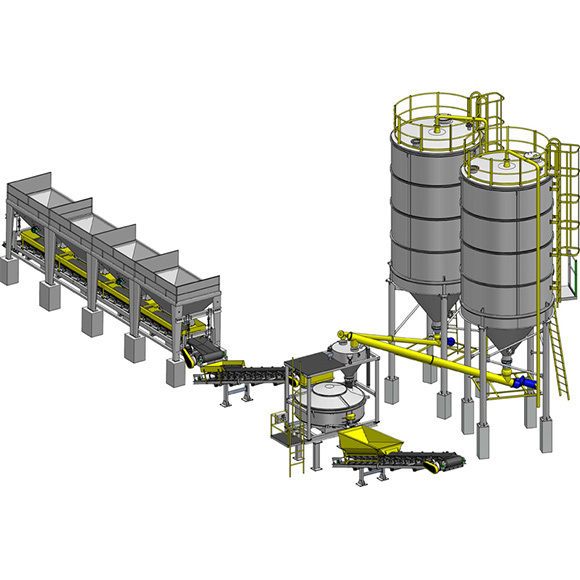

The central feeding system is a highly automated and intelligent material supply and distribution system, widely used in the production and processing of plastic products. This system has many advantages and functions, which can significantly improve production efficiency, reduce costs and environmental pollution, and enhance the market competitiveness of enterprises. This article will delve into the advantages and functions of central feeding systems, as well as how they can bring practical benefits to plastic product production.

Firstly, the intelligent and user-friendly design of the central feeding system is one of its main advantages. The system adopts a visual touch screen and human-machine interface, making operation and monitoring intuitive and simple. Through this design, users can directly monitor the screen system, understand the shortage and full material situation of each molding equipment, and display each set value and actual value. At the same time, the system can also display alarm information and help diagnose faults, making the production process more stable and reliable. In addition, the central feeding system has low noise and less waste. The fully automatic sealed stainless steel pipeline feeding operation can significantly reduce waste on raw materials, reduce noise, ensure that raw materials are not contaminated, and improve the comfort and safety of the working environment.

Secondly, the flexible design and long service life of the central feeding system are another advantage. This system can provide personalized central material supply solutions according to customer needs. Different workshop characteristics and raw material usage requirements can be designed according to actual needs to optimize the production process of customers' products. The central raw material distribution station and automatic raw material distribution station are one of the main components of the central material supply system. These distribution stations can be switched freely and transported to multiple machines, with a maximum of 20 types. In addition, due to the use of a centralized dust recovery system in the system, cleaning is more convenient and the environmental protection effect reaches the standard of 100000 level clean room operation. The clean forming space can reduce the difficulty of handling dust absorbed by static electricity in the finished product and improve product quality. Overall, the flexible design and long usage cycle of the central feeding system can effectively improve production efficiency and reduce costs, making enterprises more competitive in the market.

Thirdly, the centralized management and dust recovery of the central feeding system is another advantage. In traditional production processes, a large amount of dust and waste are generated, which not only affects production efficiency but also pollutes the environment. The use of a central feeding system can solve this problem. The system adopts a unique centralized dust recovery system, which is more convenient to clean and environmentally friendly, and meets the requirements of a 100000 level clean room operation standard. The clean forming space can reduce the difficulty of handling dust absorbed by static electricity in finished products and improve product quality. In addition, the centralized use of drying equipment minimizes the number of drying barrels used, protects the working environment of the molding site, and reduces the energy consumption of the dehumidification dryer. Due to the isolation of the drying waste gas from the site, the temperature at the forming site has significantly decreased, while reducing the pollution and waste caused by the scattering of raw materials during cleaning, completely improving air pollution and dust pollution.

RELATED NEWS

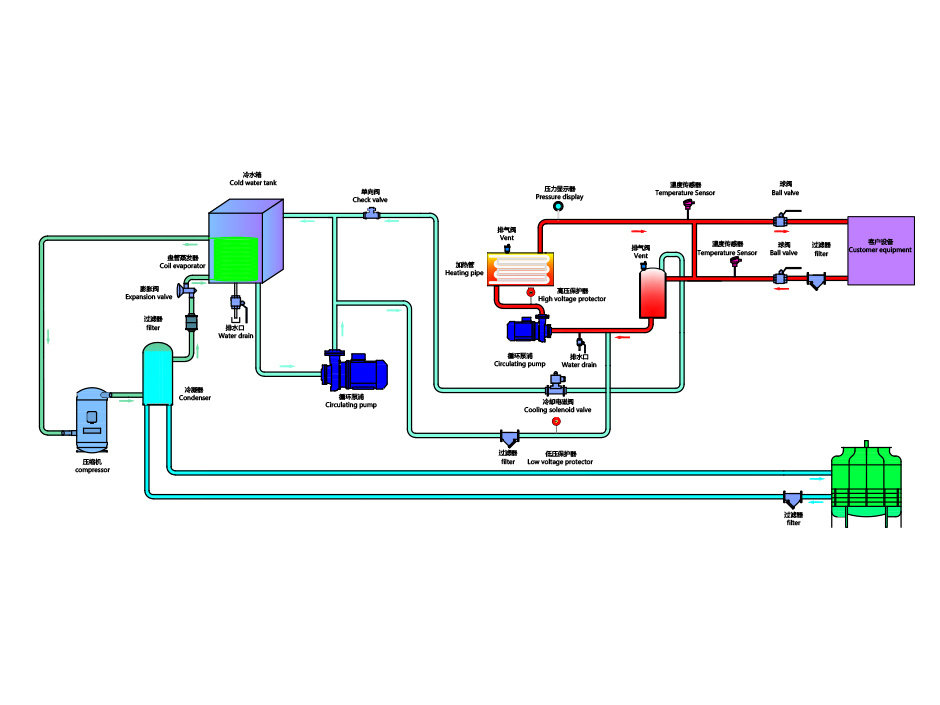

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Exploration of LSR Forming Measurement and Mixing System

Liquid silicone rubber (LSR) is a two component reactive chemical with a certain viscosity and consistency similar to that of a paste. Before forming, the A&B components of LSR will be transported to users in 20 liter barrels, 200 liter barrels, or some small disposable plastic cylinders of medical grade silicone.

Do you have any questions?

If you have any questions, please follow our continuous updates!

CONTACT >这里是标题一h1占位文字

A professional manufacturer dedicated to planning the entire plastic molding automation peripheral auxiliary system for the entire factory.

© Copyright 2023 Jiangxi Danlead Advantages Machinery Technology Co., Ltd Powered by www.300.cn SEO Supports IPV6

语言选择

语言选择