News detail

What is the difference between a regular mold temperature machine and a multi machine integrated mold temperature machine?

2023-04-18

Do you know what a multi machine integrated mold temperature machine is?

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

In limited space, the mold temperature function is required to provide multiple temperature control functions, so Hunan Zhongneng Temperature Control has launched a multi machine integrated mold temperature machine.

1. Ordinary mold temperature machine

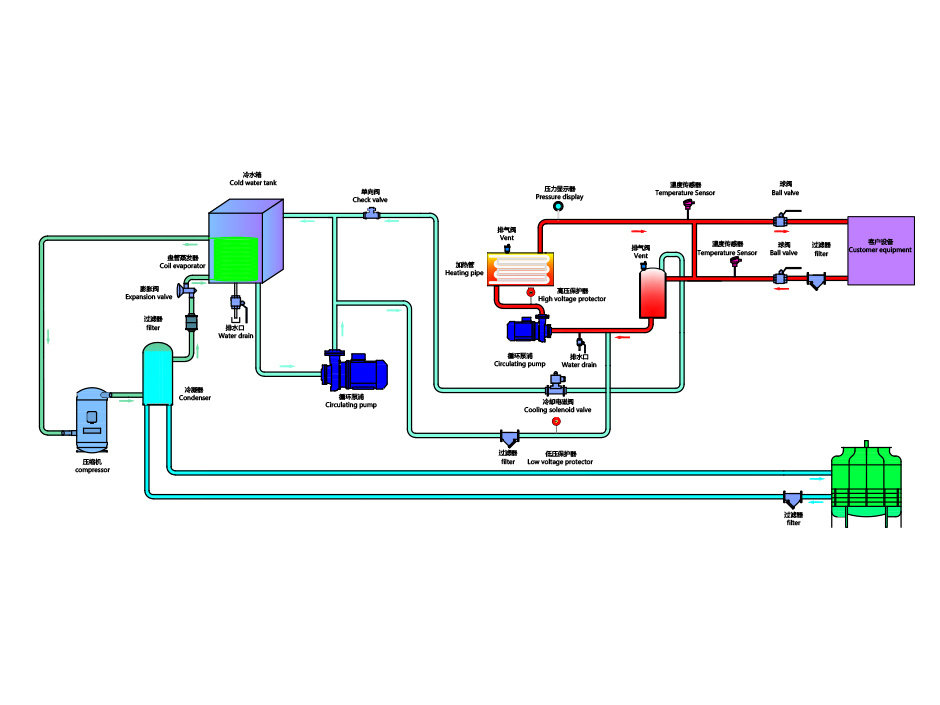

The ordinary mold temperature machine comes standard with a complete temperature control system.

Taking the 200 ℃ oil temperature machine as an example, this oil temperature machine is applied in injection molding and can provide precise temperature control within the range of room temperature to 200 ℃. The heating and cooling control are very intelligent, and the single point temperature control effect is fast and good.

2. Dual machine integrated mold temperature machine

There are two types of integrated mold temperature machines: dual temperature mold temperature machines and integrated cold and hot mold temperature machines.

Dual temperature mold temperature machine refers to two independent mold temperature machine systems in the same unit, which can control different temperatures separately.

The integrated cold and hot mold temperature machine combines the mold temperature machine and the water chiller into one. One set of mold temperature machine system and one set of water chiller system are designed to be placed in the same rack, which can meet the scene requirements of large differences in process temperature requirements during the production process and more efficient and accurate cooling requirements.

In general, dual temperature mold thermometers are commonly used for temperature control in industries such as hot pressing, automotive interior parts, die-casting mold temperature control, zinc magnesium aluminum alloy die-casting, and chemical reaction kettles.

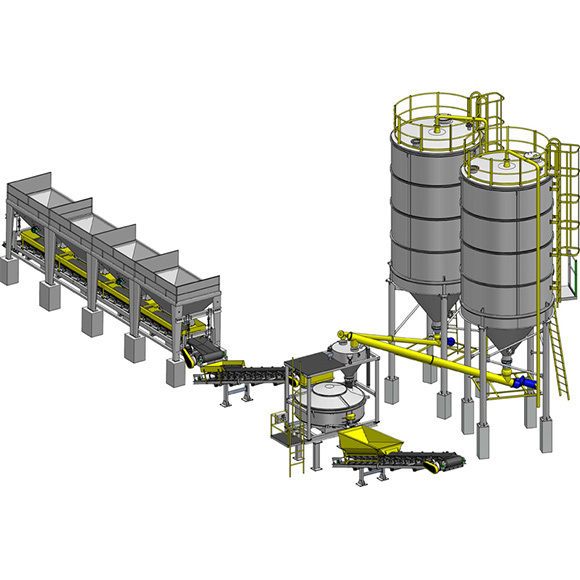

3. Three machine integrated mold temperature machine

The three machine integrated mold temperature machine is often used in three roller rolling machines, three roller calenders, etc., and three different temperature equipment are required to control the temperature during the production process.

Common three machine integrated mold temperature machines include 120 ℃ water type, 160 ℃ water type, 200 ℃ oil type, and 300 ℃ oil type. The temperature control range is different, and the design of the mold temperature machine body is also different. In terms of color matching, it is selected according to customer preferences.

Special three machine integrated mold temperature machines include a combination of cold and hot integrated mold temperature machines, a cooling system, and two mold temperature machine systems.

4. Multi machine integrated mold temperature machine

The customized multi machine integrated equipment also has specifications for six machine integrated, eight machine integrated, nine machine integrated, and eleven machine integrated mold temperature machines. With the current mature and safe production and manufacturing level of mold temperature machines, it fully meets the needs of customers for more than three types of temperature control.

Humanized appearance design, practical and convenient operation, and more reasonable maintenance and disassembly; The internal pipeline design is simple and smooth, with a compact structure, effectively reducing energy loss.

A mold temperature machine can provide several temperatures according to the desired temperature, and everyone can choose the suitable mold temperature machine according to their own needs.

RELATED NEWS

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Exploration of LSR Forming Measurement and Mixing System

Liquid silicone rubber (LSR) is a two component reactive chemical with a certain viscosity and consistency similar to that of a paste. Before forming, the A&B components of LSR will be transported to users in 20 liter barrels, 200 liter barrels, or some small disposable plastic cylinders of medical grade silicone.

Do you have any questions?

If you have any questions, please follow our continuous updates!

CONTACT >这里是标题一h1占位文字

A professional manufacturer dedicated to planning the entire plastic molding automation peripheral auxiliary system for the entire factory.

© Copyright 2023 Jiangxi Danlead Advantages Machinery Technology Co., Ltd Powered by www.300.cn SEO Supports IPV6

语言选择

语言选择