News detail

What are the advantages of cold and hot oil switching mold temperature machines and their differences from ordinary mold temperature machines

2023-04-18

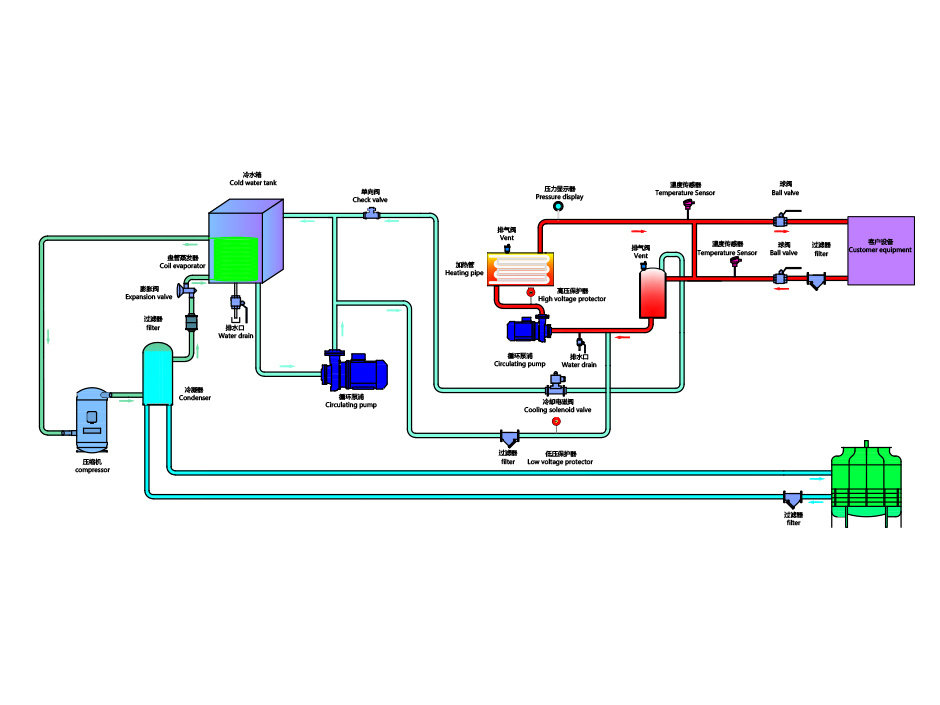

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Unlike ordinary cold and hot mold temperature machines, the cold and hot oil switching mold temperature machine can achieve self circulation of the heating and cooling system, keeping the heat transfer oil in the state of high-temperature hot oil or low-temperature cold oil, effectively reducing the energy consumption caused by the temperature of the heat transfer oil rising from room temperature to process temperature, and is efficient and energy-saving. In addition, it adopts advanced electronic technology and high-precision control technology to achieve precise temperature control and precise control of the temperature of the heat transfer oil, thereby achieving the goal of precise control of processing process parameters. It has the advantages of saving energy, reducing emissions, and reducing costs, making it an ideal alternative to traditional process equipment.

Specifically, the advantages of a cold and hot oil switching mold temperature machine are manifested in the following three aspects:

1. More energy-efficient.

The primary advantage of the cold and hot oil switching mold temperature machine is energy conservation. The cold and hot oil switching mold temperature machine adopts a three-way valve, which can switch the heating system and cooling system, thereby achieving rapid cooling and energy-saving purposes. Through this method, energy loss during the heating process can be effectively reduced, the operational efficiency of the equipment can be accelerated, and the maintenance cost of the equipment can be reduced. In addition, this switching method can also achieve more precise temperature control, improve production efficiency, and ensure product quality. In addition, this switching method can also reduce energy consumption and pollution emissions, thereby contributing to environmental protection.

2. More convenient operation.

The operation of the hot and cold oil switching mold temperature machine is more convenient compared to ordinary mold temperature machines. The hot and cold oil switching mold temperature machine adopts PLC touch screen automatic control, so that workers can set the temperature demand when operating, without the need to manually adjust heating or cooling. Simply press the switch button to complete the system control work, making the operation more simple and convenient. After setting the process, it will run according to the set program, greatly reducing manual operation time, which is currently the configuration for customers in the manufacturing industry to achieve process automation.

For example, the EXDIIBT4 explosion-proof hot and cold switching heat transfer oil furnace commonly used in the chemical industry uses a hot and cold oil switching method for temperature control. Multiple sets of products with different specifications can be provided according to customer requirements, and dual furnace heat circulation heat transfer oil can be provided for users to choose from. Real time digital display of pressure value, frequency conversion pump circulating heat transfer oil, with remote control function, convenient for user operation and use.

3. Improved security protection.

Ordinary mold temperature machines will have protective measures such as missing media, reverse direction, and overload. As a non-standard customized device, cold and hot oil switching mold temperature machines naturally have more comprehensive safety protection measures. After all, the overall pipeline layout and control have been improved. Without comprehensive safety protection, it is quite dangerous, so there are some pressure relief protection and regular maintenance reminders, The heating tube operates for a long time, automatically distributes and provides comprehensive protection. When the mold temperature reaches the set value, heating can be automatically stopped.

The cold and hot oil switching mold temperature machine has the advantages of high efficiency, energy conservation, convenient use, temperature stability, and safe and reliable operation. It is usually used for temperature control (heating and cooling) of equipment such as molds, pressure plates, rollers, and reaction kettles, especially in the chemical industry. The cold and hot oil switching control temperature, fast heating and cooling, and multi-point temperature control can meet the temperature control requirements of different industries. It is an indispensable temperature control equipment in modern industrial production.

RELATED NEWS

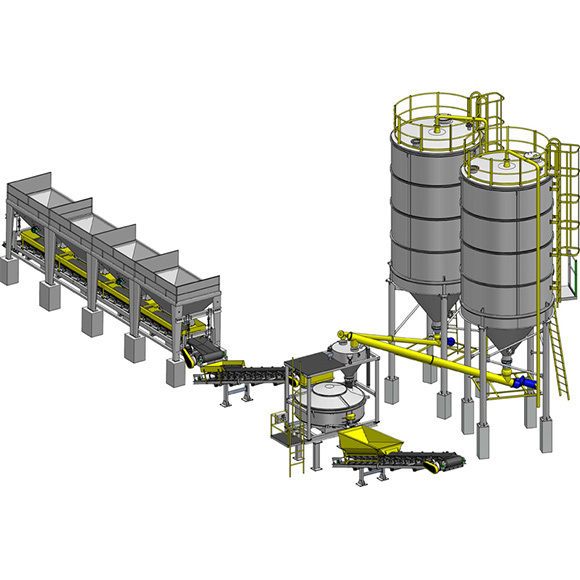

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Exploration of LSR Forming Measurement and Mixing System

Liquid silicone rubber (LSR) is a two component reactive chemical with a certain viscosity and consistency similar to that of a paste. Before forming, the A&B components of LSR will be transported to users in 20 liter barrels, 200 liter barrels, or some small disposable plastic cylinders of medical grade silicone.

Do you have any questions?

If you have any questions, please follow our continuous updates!

CONTACT >这里是标题一h1占位文字

A professional manufacturer dedicated to planning the entire plastic molding automation peripheral auxiliary system for the entire factory.

© Copyright 2023 Jiangxi Danlead Advantages Machinery Technology Co., Ltd Powered by www.300.cn SEO Supports IPV6

语言选择

语言选择