News detail

What are the advantages and characteristics of the central centralized feeding system?

2023-04-18

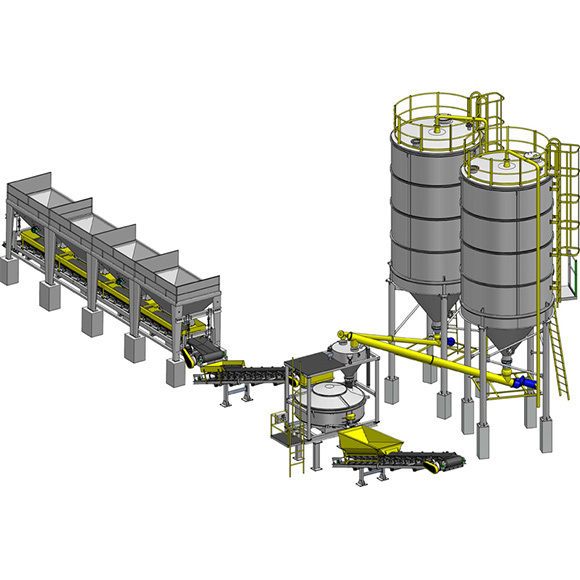

The central centralized feeding system is one of the advanced feeding solutions in the plastic industry. It adopts a special feeding technology that manages the supply of various raw materials and the control of plastic cells through a central control system, thereby saving costs and achieving efficient filling effects. The main features are:

1. Shield the impact of the on-site environment, reduce machine pollution, and reduce costs. It has excellent functions such as dust prevention, moisture prevention, and wind resistance, making it safer and more reliable.

2. Equipped with automatic adjustment function, it can ensure balanced and orderly work between raw materials and plastic cells during filling, improving the quality and efficiency of plastic processing.

3. Multiple raw material barrels can be inserted into the system, which is convenient and can complete the task of handling different plastics, making it more convenient and efficient to replace raw materials.

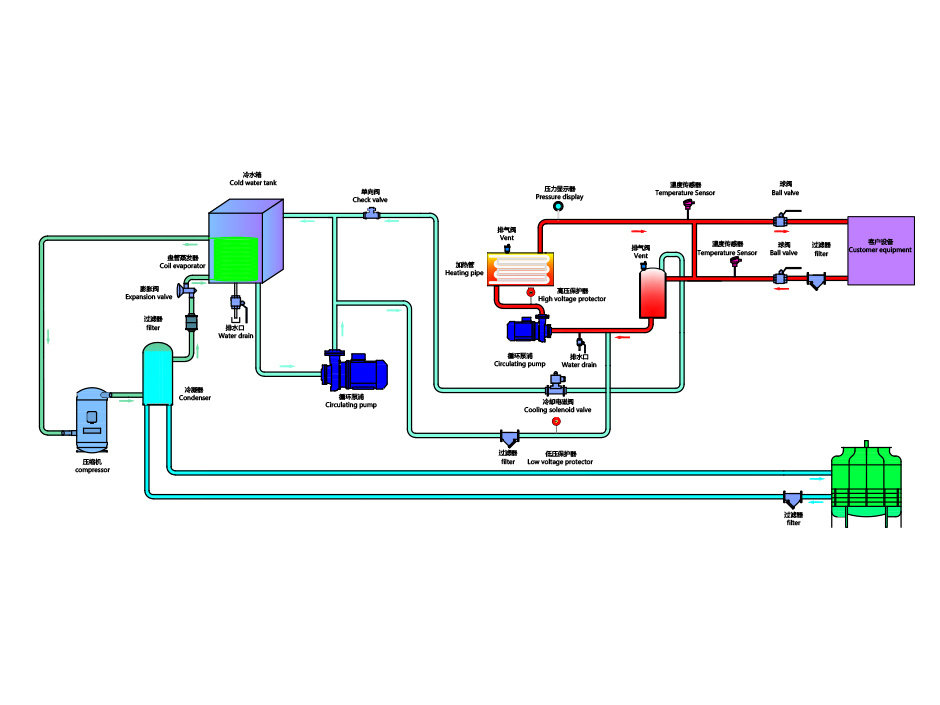

4. Adopting an advanced PLC integrated control system, it can achieve various functions such as automatic feeding, flow control, pump control, etc. It can automatically adjust temperature and pressure, achieving high efficiency consumption.

5. The integrated raw material flow meter in the system can accurately control the feed flow and achieve the best usage effect.

6. The system is equipped with a safety and convenience design, using a return to internal filter screen to reduce machine jamming, making it more stable and safe.

In summary, the central centralized feeding system is a crucial technology in the plastic processing industry, which improves the efficiency of the plastic processing industry through efficient automatic control systems and good performance, and saves costs for users.

RELATED NEWS

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Exploration of LSR Forming Measurement and Mixing System

Liquid silicone rubber (LSR) is a two component reactive chemical with a certain viscosity and consistency similar to that of a paste. Before forming, the A&B components of LSR will be transported to users in 20 liter barrels, 200 liter barrels, or some small disposable plastic cylinders of medical grade silicone.

Do you have any questions?

If you have any questions, please follow our continuous updates!

CONTACT >这里是标题一h1占位文字

A professional manufacturer dedicated to planning the entire plastic molding automation peripheral auxiliary system for the entire factory.

© Copyright 2023 Jiangxi Danlead Advantages Machinery Technology Co., Ltd Powered by www.300.cn SEO Supports IPV6

语言选择

语言选择