News detail

The control system of the dehumidifier dryer is very precise and continues to exert force in the new energy vehicle industry

2023-04-18

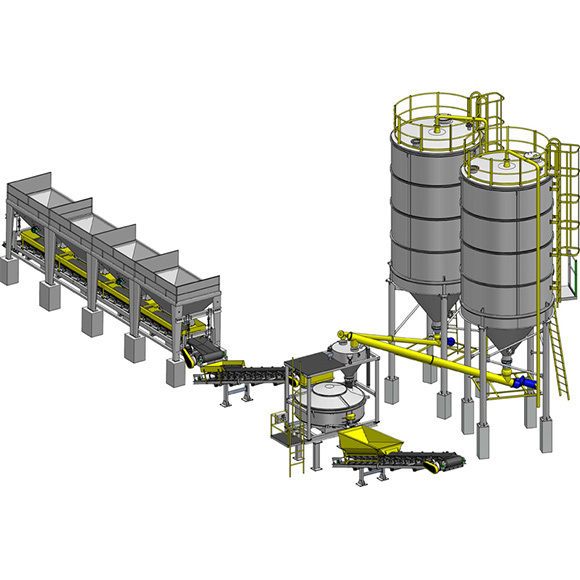

Dehumidification dryer is a dehumidification and drying treatment equipment that does not require cooling water. It can be applied in the injection molding industry to effectively prevent the generation of defective products and the risk of returns, which determines its effectiveness.

The dehumidification dryer not only has a compact structure, small installation area, small volume, and convenient operation, but also can provide stable and reliable air volume to maintain constant humidity of plastic raw materials, thereby achieving the drying, transportation, and storage of plastic raw materials, perfectly solving the problem of conveying defective products and returns, greatly reducing production costs, improving production efficiency, and becoming an indispensable equipment for the transportation of plastic raw materials in the injection molding industry.

In addition, the control system of the dehumidification dryer is very precise, which can set different feed rates and production ratios, intelligently adjust according to different temperatures and humidity, and achieve automatic control, automatically adjust temperature and humidity, accurately control temperature and humidity, and achieve precise dehumidification and drying treatment.

Dehumidifying dryers can effectively prevent viscosity changes, resist acid and alkali corrosion, resist environmental erosion, inhibit non crystallization and rusting, prevent the formation of oxide films, maintain the quality of plastic raw materials, protect the strength of plastic raw materials, and effectively save electricity consumption, improve environmental conditions, and ensure the stability of product quality.

The dehumidification dryer is a highly functional dehumidification and drying equipment that can meet the different needs of the plastic storage and transportation industry. It effectively dehumidifies and dries, saves energy consumption, ensures the drying, transportation, and storage of plastic raw materials, greatly reduces the generation of defective products, and protects the quality of products. It can be said that dehumidification dryers are absolutely essential equipment for the transportation of plastic raw materials.

RELATED NEWS

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

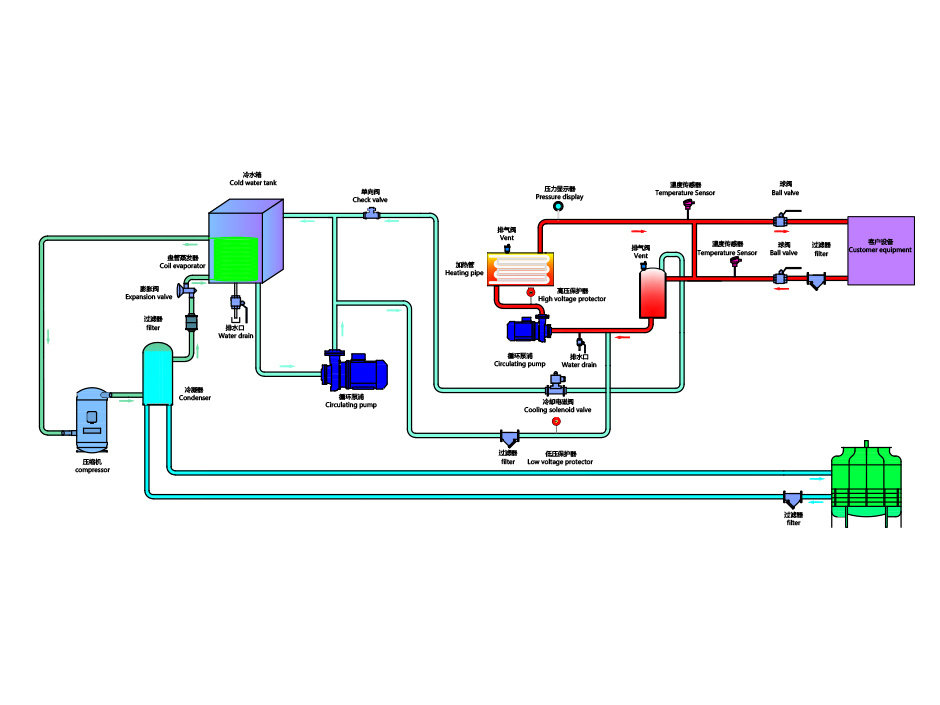

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Exploration of LSR Forming Measurement and Mixing System

Liquid silicone rubber (LSR) is a two component reactive chemical with a certain viscosity and consistency similar to that of a paste. Before forming, the A&B components of LSR will be transported to users in 20 liter barrels, 200 liter barrels, or some small disposable plastic cylinders of medical grade silicone.

Do you have any questions?

If you have any questions, please follow our continuous updates!

CONTACT >这里是标题一h1占位文字

A professional manufacturer dedicated to planning the entire plastic molding automation peripheral auxiliary system for the entire factory.

© Copyright 2023 Jiangxi Danlead Advantages Machinery Technology Co., Ltd Powered by www.300.cn SEO Supports IPV6

语言选择

语言选择