News detail

Why does injection molding require drying of plastic materials? Is moisture content reduced through dehumidification and drying technology?

2023-04-18

Many plastics absorb moisture from the air, and the amount they absorb depends on the type of resin. The moisture in plastic particles, even surface condensed moisture, can cause some problems related to the molding and processing of engineering plastics. This water absorption performance may have some adverse effects, including problems during processing, poor surface of the product, or poor mechanical properties of the product. It is indeed difficult to determine the presence of moisture solely by visual observation. This article will provide some useful guidance for the molding process of various plastics that need to be processed, and how to handle plastics that are sensitive to moisture.

Drying plastic materials

Most engineering plastics require the moisture content in the particles to be below a certain maximum value, and whether the plastic needs to be dried mainly depends on the sensitivity of the raw material to moisture. In general, the moisture content of plastic materials is related to transportation conditions, packaging type, and storage time. For example, polyamide (PA) is generally transported in bags, which use aluminum foam as a waterproof layer, so when in use, the bag can be directly opened to remove the material and used. But most polyamide (nylon) processing plants require the raw resin to be dried first, although some people believe that if the plastic is used for less than an hour, it does not need to be dried

On the other hand, PET and PBT are very sensitive to moisture and must be dried to ensure that the impact strength of the product is not affected. In addition, these resins will quickly absorb water again after drying, so in some cases, processing manufacturers must be particularly careful to avoid using open containers during the transportation and transportation of PBT and PET resins, while also considering the residence time of the resin in the loading hopper. In adverse climatic environments, PET can absorb water even exceeding the maximum allowable moisture content of the product by 0.02% within 10 minutes. Special attention should be paid to recycled materials after drying and crushing, or granular materials that have been saturated with water absorption (such as when placed in containers under open conditions). In this case, the recommended drying time often does not meet the needs. Fully saturated polyamide nylon should be dried for at least 12 hours. Under such dry conditions, yellowing of the material is actually inevitable

RELATED NEWS

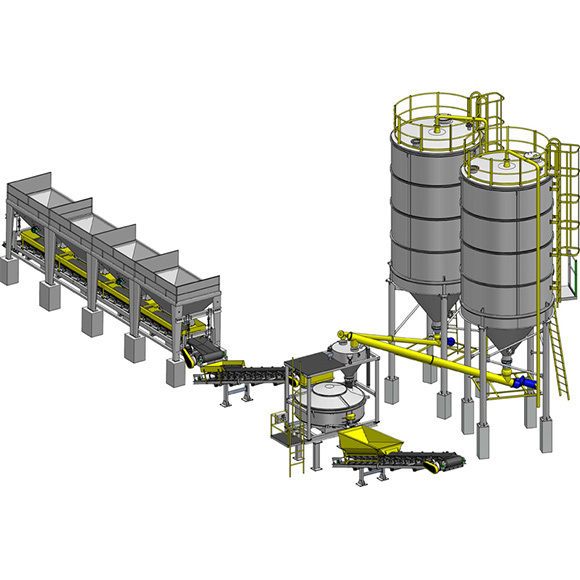

For special processes, customers require temperature control for multiple equipment or several different processes (formulas) in a production process, requiring precise control of multiple different temperatures.

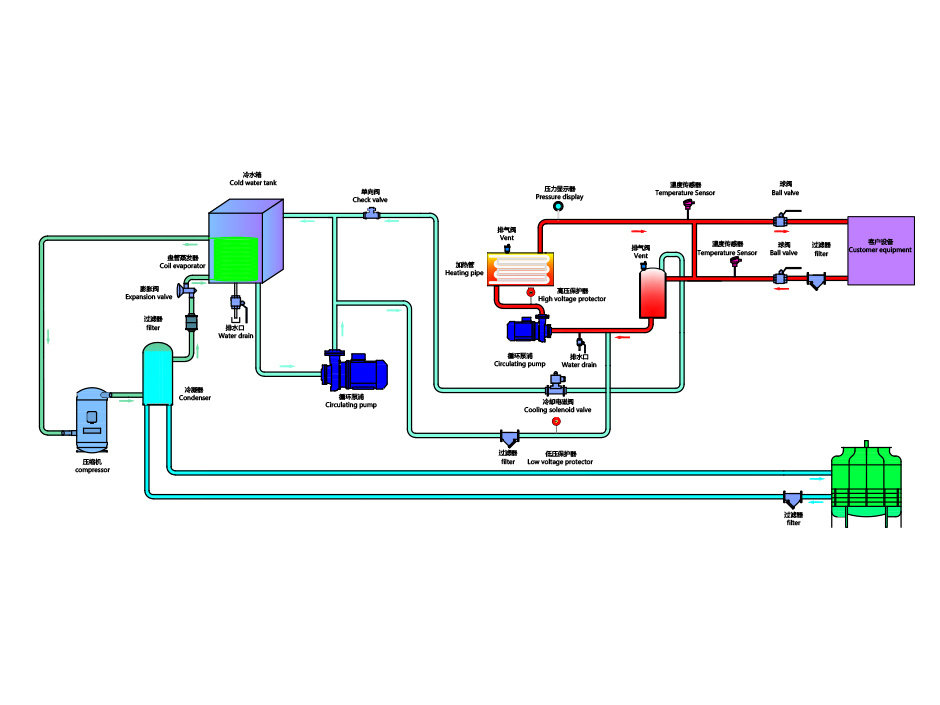

The hot and cold oil switching mold temperature machine is a non-standard equipment that includes two parts: the heating part and the cooling part. It needs to be customized according to specific needs from the mold temperature machine manufacturer. A high-precision and highly reliable temperature control system is adopted to achieve automatic circulation of heating and cooling processes, and can achieve precise control and switching of heating and cooling temperatures.

Exploration of LSR Forming Measurement and Mixing System

Liquid silicone rubber (LSR) is a two component reactive chemical with a certain viscosity and consistency similar to that of a paste. Before forming, the A&B components of LSR will be transported to users in 20 liter barrels, 200 liter barrels, or some small disposable plastic cylinders of medical grade silicone.

Do you have any questions?

If you have any questions, please follow our continuous updates!

CONTACT >这里是标题一h1占位文字

A professional manufacturer dedicated to planning the entire plastic molding automation peripheral auxiliary system for the entire factory.

© Copyright 2023 Jiangxi Danlead Advantages Machinery Technology Co., Ltd Powered by www.300.cn SEO Supports IPV6

语言选择

语言选择